As a gemstone, sapphire is highly valued for its deep blue color, though it can also occur in other colors such as yellow, pink, or colorless. In the realm of jewelry, the value of sapphire materialdepends on its hue, transparency, and quality of cut. It is commonly used in the creation of rings, necklaces, and earrings, cherished by many as precious collectibles.

In addition to naturally occurring sapphire, modern technology allows for the synthesis of lab-grown sapphire. These synthetic gemstones often mimic the appearance and physical properties of natural stones but at a lower cost, hence they are extensively used in commercial and technological applications.

In summary, sapphire material is not only a beautiful gemstone but also a critically important material in both industry and technology. Its wide-ranging uses and profound impact make it a vital component of the modern world.

What are the methods of growing sapphire material?

There are several methods used for growing sapphire crystals, each with its own advantages and suitability for different applications. Here are the main methods:

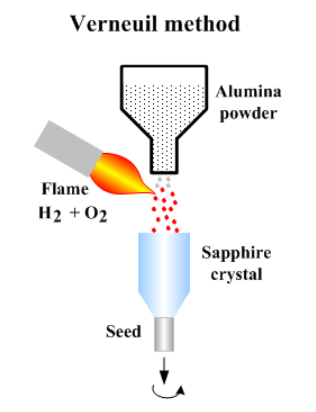

Verneuil (Flame Fusion) Method:

- This is one of the oldest and most common methods for producing synthetic sapphire material

- A powdered aluminum oxide (Al2O3) feedstock is melted in a high-temperature oxyhydrogen flame (around 2000°C).

- The molten material drips down and solidifies on a rotating pedestal, forming a cylindrical boule of sapphire.

Czochralski (CZ) Method:

- This method is widely used for growing single crystals of various materials, including sapphire material.

- A seed crystal of sapphire is dipped into a crucible containing molten aluminum oxide.

- The seed crystal is slowly pulled upwards while rotating, allowing the molten material to solidify and form a single crystal around the seed.

Kyropoulos Method:

- This method is used for growing large, high-quality single crystals of sapphire material.

- A seed crystal is placed at the bottom of a crucible filled with molten aluminum oxide.

- The crucible is slowly cooled from the top while the seed crystal is gradually pulled upwards.

- As the molten material crystallizes on the seed, a large single crystal of sapphire is formed.

Heat Exchanger Method:

- In this method, a seed crystal is placed on a heat exchanger plate.

- Aluminum oxide powder is heated above its melting point and fed onto the seed crystal.

- The heat exchanger plate rapidly cools the molten material, promoting crystal growth on the seed.

Edge-Defined Film-Fed Growth (EFG) Method:

- This method involves feeding molten aluminum oxide through a small slit onto a rotating, crystallized seed.

- A thin film of sapphire grows on the seed as it rotates, forming a continuous sheet.

- This sheet can be further processed into various shapes and sizes suitable for specific applications.

Based on different methods for growing sapphire material, each approach has its own advantages and disadvantages, suited to various application needs. Here’s an analysis of each method:

Verneuil (Flame Fusion) Method:

- Advantages:

- Fast production speed, suitable for mass production.

- Can produce relatively large sapphire crystals at lower costs.

- Generally produces crystals of acceptable quality for industrial and commercial applications.

- Disadvantages:

- Crystal quality may not be as high as other methods, with potential for bubbles and impurities.

- Sacrifices some purity and crystal structure compared to other methods.

Czochralski (CZ) Method:

- Advantages:

- Capable of producing high-quality, large single crystals of sapphire.

- High crystal purity, suitable for demanding optical and semiconductor applications.

- Disadvantages:

- Slower production speed, relatively higher cost.

- Limited by crystal size and quality, less suitable for large-scale production.

Kyropoulos Method:

- Advantages:

- Can grow large, high-quality single crystals of sapphire.

- High crystal quality with excellent optical and mechanical properties.

- Disadvantages:

- Long production cycle, relatively high cost.

- Complex equipment and operations requiring specialized technical expertise and facilities.

Heat Exchanger Method:

- Advantages:

- Can grow high-quality sapphire crystals in a shorter time frame.

- Lower energy consumption and costs compared to other methods.

- Disadvantages:

- Limited control over crystal size and shape.

- Growth rate may not be as stable as other methods.

Edge-Defined Film-Fed Growth (EFG) Method:

- Advantages:

- Capable of growing large area and thin sapphire crystal sheets.

- Suitable for applications requiring large-area crystals.

- Disadvantages:

- Crystal quality and purity slightly lower compared to other methods.

- Complex manufacturing process with high equipment and process requirements.

In conclusion, the choice of the growth method depends on specific application requirements. For high-quality, large single crystals of sapphire material, CZ and Kyropoulos methods are ideal choices; whereas for large-scale industrial production, the Verneuil method may be more economical. Each method has unique advantages and limitations that should be carefully considered based on practical needs and constraints.

What are the applications of Sapphire material?

We will elaborate on the industrial applications and jewelry industry uses of sapphire.

What are the industrial uses of sapphire?

Optical Applications:

- Windows and Lenses: Sapphire is highly transparent and has excellent optical properties, making it ideal for manufacturing optical windows and lenses. It is widely used in laser technology, optical instruments, and camera lenses, providing superior optical clarity and abrasion resistance.

- Sensors: Due to its stable physical and chemical properties, sapphire is employed as window and coating material in optical sensors used for medical diagnostics, environmental monitoring, and scientific research.

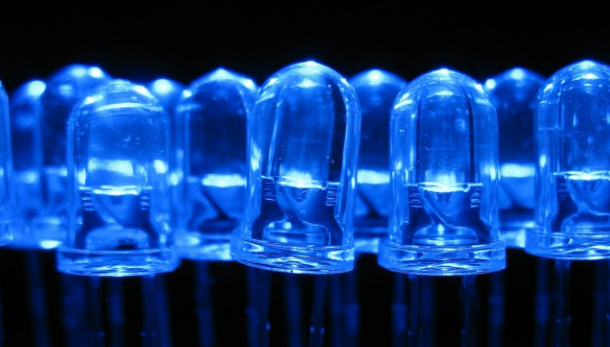

Semiconductor Industry:

- Substrate Material: Single-crystal sapphire material serves as an alternative to silicon substrates in the manufacturing of electronic and optoelectronic devices. It offers a highly flat surface and good thermal stability, making it crucial for producing high-performance semiconductor devices.

- Insulating Layer: In semiconductor processes, sapphire material is used as an insulating layer material to isolate and protect the component structures of electronic devices, ensuring stable electrical performance and long-term reliability.

Chemical and Industrial Wear-Resistant Materials:

- Nozzles and Bearings: sapphire material’s high hardness and wear resistance make it suitable for use in nozzles and bearings for chemical and industrial equipment. It withstands wear under high temperature and pressure conditions, prolonging equipment lifespan and enhancing efficiency.

- Cutting Tools: In industrial machining, sapphire is utilized as blades and tools for cutting tasks requiring high precision and wear resistance.

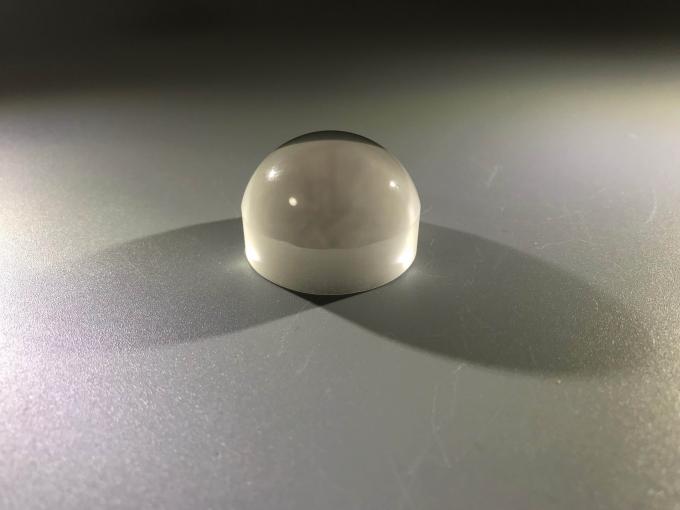

Introducing our Sapphire Glass Ball Lens, a revolutionary component poised at the forefront of cutting-edge medical technology. Crafted with precision and durability in mind, thisSapphire Glass Ball Lens stands as a beacon of innovation, enhancing the capabilities of medical devices across various applications.

In summary, sapphire material, as a form of aluminum oxide, is highly valued in industrial applications for its high hardness, excellent optical properties, and chemical stability. From optical devices to semiconductor technologies and chemical equipment, sapphire plays a critical role in supporting advancements in modern science, technology, and industry.

What are the jewelry industry uses of sapphire?

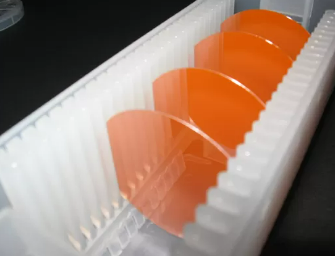

Synthetic colored sapphire possesses distinct characteristics that make it a versatile alternative to natural gemstones. Here’s an elaboration on how colored synthetic sapphire material can be created:

- Formation Process: Synthetic colored sapphire is typically created through the Verneuil (flame fusion) method or the Czochralski method. In the Verneuil method, powdered aluminum oxide (Al2O3), along with small amounts of specific trace elements or dopants, is melted in a high-temperature flame. As the molten material cools and solidifies on a rotating pedestal, it forms a synthetic sapphire material crystal with the desired coloration. This method allows for the controlled introduction of elements like titanium, chromium, or iron, which impart various colors such as blue, yellow, pink, or green.

- Color Control: The color of synthetic sapphire can be precisely controlled by adjusting the composition of dopants or trace elements during the synthesis process. For instance, titanium and iron produce blue sapphire material, while chromium yields pink or red hues. This ability to manipulate coloration makes synthetic sapphires highly desirable for jewelry and industrial applications where specific color requirements must be met.

- Physical Properties: Synthetic colored sapphire material exhibit similar physical properties to natural sapphires, including excellent hardness (9 on the Mohs scale), high durability, and resistance to scratching and abrasion. They also possess good optical clarity, making them suitable for faceting into various cuts and shapes for jewelry purposes.

- Applications:

- Jewelry: Colored synthetic sapphire material are widely used in jewelry as affordable alternatives to natural gemstones. They are crafted into rings, earrings, necklaces, and other jewelry pieces, offering vibrant colors and durability at a lower cost compared to natural sapphires.

- Industrial Uses: Beyond jewelry, synthetic colored sapphires find applications in optics, electronics, and precision engineering. Their hardness and optical properties make them suitable for use in laser technologies, optical windows, and sensors.

- Availability and Cost: Synthetic colored sapphire materials are produced in large quantities and are readily available in various colors and sizes. They are generally more affordable than their natural counterparts, making them accessible to a wider range of consumers and industrial applications.

In conclusion, synthetic colored sapphires are engineered to meet specific color preferences while maintaining the desirable properties of natural sapphire materials. Their versatility, durability, and cost-effectiveness make them indispensable in both decorative and technical applications worldwide.

Synthetic sapphire gemstone showcase

The color characteristics of synthetic royal blue sapphire gemstones include deep, vivid hues resembling natural gems. Material advantages include high hardness, excellent durability, and affordability for jewelry and industrial uses.

The color characteristics of synthetic ruby gemstones include vibrant red hues resembling natural rubies. Material advantages include high hardness, excellent durability, and affordability for jewelry and industrial uses. ..

Answering other related questions

Is a sapphire an expensive stone?

Yes, sapphires are generally considered to be expensive gemstones, especially those of high quality and larger sizes. The price of a sapphire material can vary significantly based on factors such as color, clarity, cut, and carat weight. Blue sapphires, particularly those with deep, vivid hues and good transparency, tend to command higher prices due to their rarity and popularity in the jewelry market.

Synthetic gemstones offer significant value due to their controlled production processes, which ensure consistent quality and availability. They provide affordable alternatives to natural gemstones while maintaining desirable physical and optical properties. This accessibility makes them popular choices in both jewelry and industrial applications, where their durability and cost-effectiveness are advantageous. Additionally, synthetic gemstones contribute to reducing environmental impact associated with mining, further enhancing their value in sustainable practices.

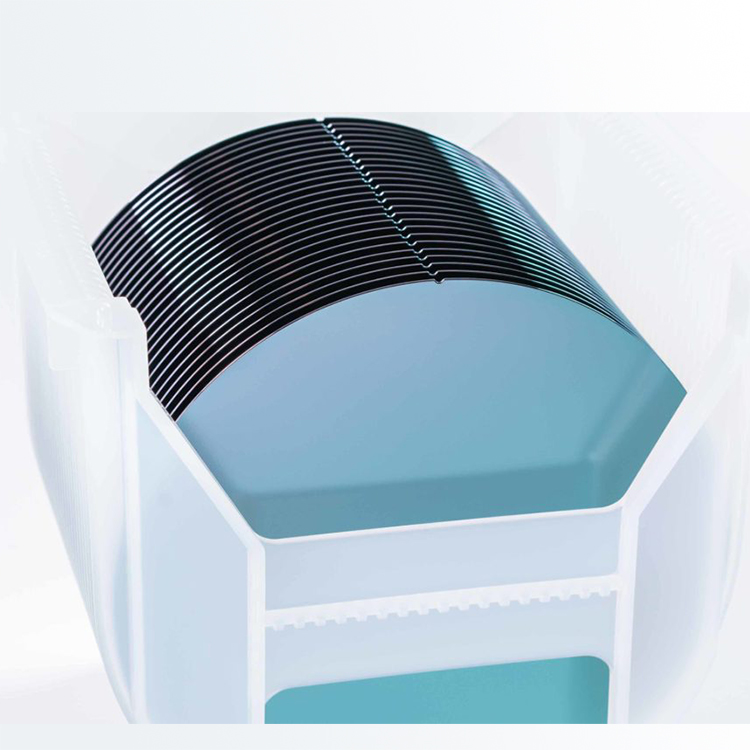

What is a sapphire wafer?

A sapphire wafer refers to a thin, flat piece of sapphire crystal that is typically used as a substrate or base material in various technological applications. These wafers are manufactured from synthetic sapphire, which is grown into large crystals and then sliced into thin discs or wafers of precise thickness and orientation.

The main characteristics and uses of sapphire material wafers include:

- Material Properties: Sapphire wafers are prized for their high hardness (second only to diamond), excellent optical transparency across a wide spectrum, high thermal conductivity, and resistance to chemical and mechanical damage.

- Applications:

- Semiconductor Industry: Sapphire wafers serve as substrates for manufacturing electronic devices, such as LEDs (Light Emitting Diodes) and laser diodes. They provide a stable and electrically insulating surface that can withstand high temperatures and harsh conditions.

- Optics: Due to their optical clarity and durability, sapphire wafers are used in optical windows, lenses, and components for scientific instruments, cameras, and lasers.

- Industrial Applications: They are also employed in harsh industrial environments as protective covers, sensor windows, and components in equipment requiring high strength and resistance to wear.

- Manufacturing Process: The production of sapphire wafers involves methods such as the Kyropoulos method or the heat exchanger method to grow large, high-quality sapphire crystals. These crystals are then precisely sliced, polished, and chemically treated to achieve the desired surface finish and specifications required for specific applications.

In summary, sapphire wafers are critical components in advanced technology and industrial sectors due to their exceptional physical properties and versatility, enabling them to be utilized in a wide range of demanding applications where durability, clarity, and reliability are paramount.

What are sapphire substrates?

Sapphire substrates refer to thin, flat pieces or discs of sapphire material that are used as a base or foundation in various technological and industrial applications. These substrates are typically manufactured from synthetic sapphire, which is grown into large, high-quality crystals and then processed into specific shapes and sizes suitable for different uses.

Here are the key aspects and applications of sapphire substrates:

- Material Properties:

- Hardness and Durability: Sapphire is one of the hardest materials, second only to diamond, which makes sapphire substrates highly resistant to scratching and wear.

- Optical Transparency: sapphire material exhibits excellent optical clarity and transparency over a wide range of wavelengths, making it suitable for optical applications.

- Chemical and Thermal Stability: It is chemically inert and can withstand high temperatures, making it suitable for harsh environments.

- Applications:

- Semiconductor Industry: sapphire material substrates are extensively used as a base material for manufacturing semiconductor devices such as LEDs (Light Emitting Diodes), laser diodes, and high-power electronic devices. They provide a stable platform with good electrical insulation properties and high thermal conductivity.

- Optics: Due to their optical clarity and high hardness, sapphire substrates are used in optical components such as windows, lenses, and mirrors for scientific instruments, cameras, and lasers.

- Industrial Applications: They serve as protective covers, sensor windows, and components in equipment requiring robust materials with high mechanical strength and resistance to corrosion.

- Manufacturing Process: The production of sapphire substrates involves growing large, single-crystal sapphire boules using methods like the Kyropoulos method or the heat exchanger method. These methods allow for the precise control of crystal growth and orientation, ensuring high quality and uniformity in the substrates produced.

In summary, sapphire substrates play a crucial role in various advanced technology and industrial applications due to their exceptional physical and optical properties. They provide a reliable and durable foundation for electronic, optical, and industrial components, contributing to the advancement of technologies that require high-performance materials.

Why is sapphire a good substrate?

Sapphire is considered a good substrate primarily due to its exceptional physical and chemical properties that make it suitable for a wide range of demanding applications in advanced technology and industrial sectors. Here are the key reasons why sapphire material is valued as a substrate:

- Hardness and Durability: Sapphire is one of the hardest materials known, second only to diamond on the Mohs scale of hardness. This property ensures that sapphire substrates are highly resistant to scratching, abrasion, and wear, making them durable and long-lasting.

- Optical Transparency: Sapphire exhibits excellent optical clarity and transparency across a broad spectrum of wavelengths, from ultraviolet (UV) to infrared (IR). This makes it ideal for optical applications where high optical transmission and minimal light scattering are crucial.

- Chemical Inertness: Sapphire is chemically inert and resistant to most chemicals, acids, and alkalis. This property makes it suitable for use in harsh chemical environments without undergoing degradation or corrosion.

- High Thermal Conductivity: sapphire material has high thermal conductivity compared to many other substrate materials. This property allows for efficient heat dissipation, which is essential for applications involving high-power electronic devices and laser diodes.

- Electrical Insulation: Sapphire is an excellent electrical insulator, which is important in semiconductor applications where electrical isolation between components is necessary to prevent short circuits and ensure reliable performance.

- Dimensional Stability: sapphire material substrates exhibit minimal thermal expansion and contraction over a wide temperature range. This dimensional stability is critical in maintaining the integrity and precision of components, particularly in high-precision optical and semiconductor devices.

- Manufacturability: Sapphire can be grown into large, high-quality crystals using advanced crystal growth techniques like the Kyropoulos method or the heat exchanger method. This allows for the production of substrates with precise orientations, sizes, and surface qualities tailored to specific application requirements.

In conclusion, sapphire material’s combination of hardness, optical transparency, chemical inertness, thermal conductivity, electrical insulation, dimensional stability, and manufacturability makes it an excellent substrate material for a variety of advanced technology and industrial applications. It provides a reliable foundation for semiconductor devices, optical components, and industrial equipment where durability, performance, and reliability are paramount.